Fascination About Motorcycle Parts New Zealand Specialists

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

Table of ContentsOur Motorcycle Parts New Zealand Specialists PDFsMotorcycle Parts New Zealand Specialists - An OverviewFacts About Motorcycle Parts New Zealand Specialists UncoveredExamine This Report about Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Basic Principles Of Motorcycle Parts New Zealand Specialists What Does Motorcycle Parts New Zealand Specialists Do?What Does Motorcycle Parts New Zealand Specialists Mean?

So, reach out to among our professionals today.CNC machining innovation is rapidly ending up being the centerpiece of various production processes around the globe as a straight result of its numerous advantages over other approaches. In addition, the markets that make motorcycles have actually gotten on board with this fad. The most ingenious firms are currently creating their engine elements and wheels making use of machining techniques originally established for motorbike parts.

You might be asking yourself why we utilize. Currently that we have your attention allow us discuss the reasoning behind this contemporary growth in the bike production industry.

3 Simple Techniques For Motorcycle Parts New Zealand Specialists

Additionally, you have total control over the look of the components, also down to the minute information. Occasionally, motorcyclists might decide to fix up their ride by mounting aftermarket components or changing the bike's makeover. As soon as once more, computer system numerical control (CNC) machining is one of the most practical approach. Upgrades may be of any type of type and design you desire.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

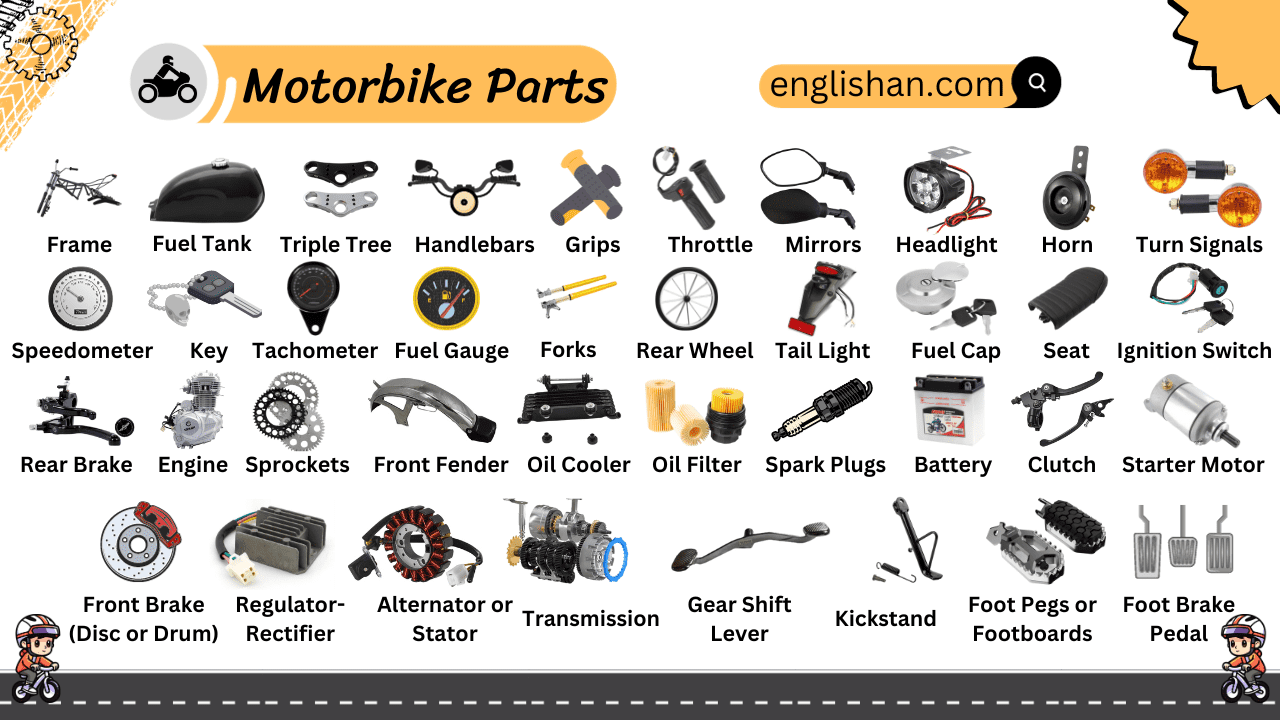

CNC machining might be utilized to make virtually all of a motorcycle's metal and plastic parts. To proceed, we'll talk about a number of machined parts for motorcycles.

When personalizing the wheels, the disks are where the emphasis should be. The bulk of them are constructed out of light weight aluminum. Light weight aluminum alloys are popular for the outstanding machining capabilities that they have. Milling treatments are used to obtain the desired level of wheel customization. An additional aspect of the bike that may be individualized is the tires.

The Buzz on Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorcycle), one of the most essential element is the engine. Several individuals suggest to it as the "heart" of the car. On the other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be intricate and call for designs with a high degree of precision.

Lighting is one more complicated aspect of customization. Use just high-quality products, nonetheless, given that these lights are important for the safety and security of motorcyclists and other vehicle drivers or people when traveling, specifically in the evening. Motorcycle headlights have 3 almosts all: the light bulb, or source investigate this site of light, the lens, and the real estate. Specifically, we tailor the lens and the real estate.

Milling processes with a perfect coating would certainly lead to the lenses having a reflective top quality that resembles that of a mirror. The cover, on the other hand, is not composed of vulnerable products; rather, it is built out of hard polymers that can be machined right into even more elaborate patterns.

What Does Motorcycle Parts New Zealand Specialists Mean?

Motorbike suppliers often cast these elements, but only for the production of bespoke components. Machining on five axes in today's globe is the methods by which any type of layout shape might be realized.

Pick Runsom for your tailored bike components! We have the capacity to produce complicated and trendy parts making your motorcycle unparalleled.

Here are a few instances of steels typically used in motorcycle element machining. Aluminum is the main product utilized by firms specializing in producing custom motorcycle parts to produce most of these parts. In the past, we would build our engines out of cast iron. On the various other hand, light weight aluminum is promptly ending up being the product of choice, partly because of the reality that it is extra lightweight.

Zinc refers to another steel that is Discover More extremely light in weight and has wonderful machining qualities as a result of its high mechanical toughness. This product might be developed right into practically any type of shape and preserves its dimensions well. Also mission-critical elements that need a high level of precision might take advantage of their usage.

About Motorcycle Parts New Zealand Specialists

Another metal that sees heavy use in the production of CNC-customized parts is magnesium. It is among the lightest steels that are currently available and has excellent machinability features and toughness appropriate with its low weight. Among the disadvantages of magnesium is that its dirt may easily ignite.

Due to the fact that of its premium machinability and weldability, stainless-steel is an alloy that is particularly fit for CNC procedures. They have excellent rust resistance and a high aesthetic appeal. Their most common use in producing numerous motorbike components is fasteners, such as screws and screws. Their low susceptibility to oxidation and Extra resources rust makes them ideal for this use.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

It appears that CNC transforming and milling are the foundational procedures. In enhancement, it requires maintaining bars of material, most usually plastic or metal, in placement and then turning a cutting device to eliminate areas of the product as the material is transformed.

These methods are just as essential and produce parts with high accuracy and consistent quality. The processes help enhance the general high quality of the machined motorcycle elements.

Fascination About Motorcycle Parts New Zealand Specialists